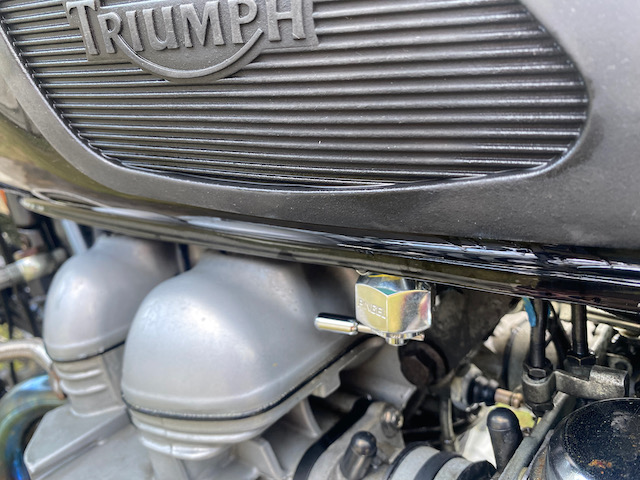

Added the last bit to the Bonneville – a Pingel petcock. The old factory petcock was weeping fuel, and I figured I go with the blingy chrome Pingel. Easier than I thought – it took less time than it took my son to take a shower – and it seals nicely.

With that, I’m pretty much done with the major work on the Triumph. It rides nicely and stops as it should. The engine purrs at idles and pulls solidly. In the next couple of months it will need a new set of sprockets and chain, primarily due to my neglect.

Next up was the scooter. It’s a 2006 Genuine Stella. Which is a rebadged LML Star. Which is an Indian manufactured clone of the Vespa PX150. I’ll probably write more on it, it has a little bit of a story, but its low miles and state of neglect is not uncommon.

And this little scooter had been marinating in its hydrocarbons for as long as my son has walked the earth. A while back I scoured the tank, replaced the petcock, and cleaned the carbs. Still, it didn’t run quite right. I went back to figure out later, and got it to run (but not idle) until it didn’t. Not only that, but the kickstarter would move. I took that as an excuse to buy parts, so I got a Malossi cylinder kit (before I even pulled the head). Over the past year, I’ve been trying hard to move away from that “buy a part” first response before I understand a problem. I’ve wasted money and time using that approach, and have only gotten frustrated. This past weekend I figured I find out what the problem was, hoping maybe it was just a jammed kickstart gear. It was not.

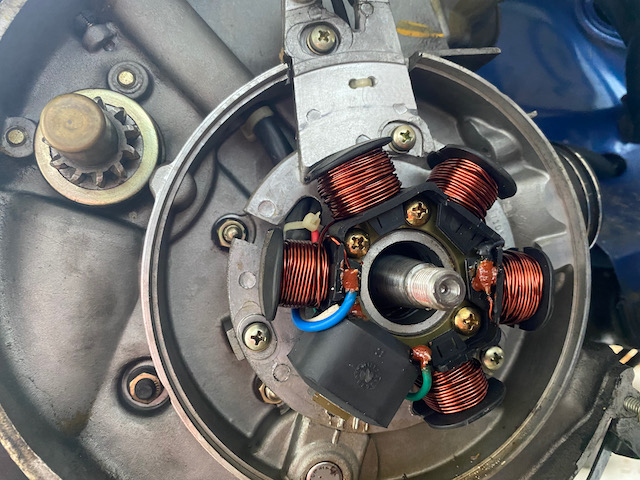

Once my minuscule flywheel puller (Italian made) came in the mail, I made it do what it was made to do. I have also learned that an investment in the right tool always pays off. I split the cases, and examined the fly side of the scooter’s soul. And it was not a good sight.

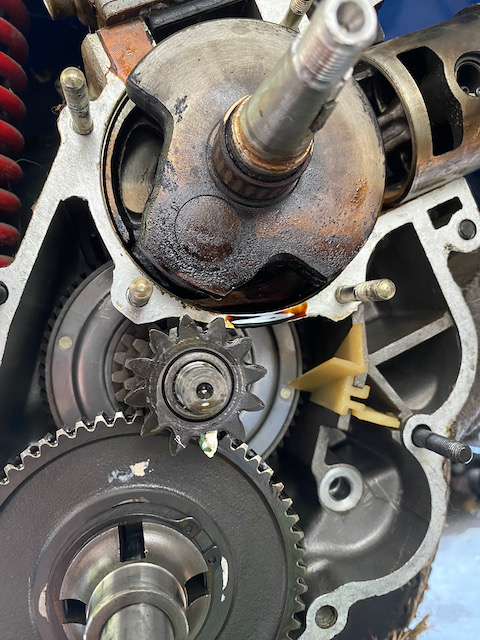

Behold the carnage. Forensically, it looks like I didn’t get the oil injection lines right when I reinstalled the carburetor. Two strokes need oil in the fuel to keep the spinning parts spinning, and the piston big end and the needle bearing just didn’t get any. Of course, at the time, my approach was to keep kicking. Lesson learned.

But the transmission looks good.

I’ve got a new crank, bearings and crankshaft install tool on order. Combined with the cylinder kit, it should add some grunt. I think this is what I need – a full rebuild with some uncharted territory, including replacing bearings, timing crankshafts, and measuring squish. I’ve always wanted to measure squish.